APU

- James Albright (a former G450 driver)

Updated: 2020-11-02

The APU is a fairly reliable piece of magic that has a finite life. It works great until it comes time to replace it. The manuals, Gulfstream and others, all seem to dive into the mechanics of the system and a lot of things that you, as a pilot, don't really care about.

What do we care about? The APU takes outside air, fuel, and battery power and converts all of that to bleed air, electrical power, exhaust, and noise. It is particular about the way it starts in various conditions, has to be shutdown in a particular fashion, and when things go wrong, it may or may not tell you.

The APU generally costs about $250 an hour to operate. It burns around 30 gallons of fuel an hour, say about $200, and typical maintenance service plans go for around $50 an hour.

There seems to be a wide range of technique and procedure on how to best operate the APU. Most of the blame for this rests with us pilots, who tend to carry over past practices to our newer aircraft. Some of the blame belongs to Gulfstream, who have not updated their 2002 Best Practices for APU Operation, published in the Breakfast Minutes, September 27, 2002. I've reproduced those below.

Everything here is from the references shown below, with a few comments in an alternate color.

APU Air

General Description

The G450 APU is about as good as it gets until you breach the newest generation of Gulfstreams (The G500 and G600), but if you are coming from a GIV, GV, G550, or even another G450, there are some things you need to know about. GIV: the APU does a good job of keeping the cabin cool on even the warmest days, so the old practice of swapping the bleeds just prior to takeoff is no longer necessary. GV and G550: there are fewer things you can do with the APU in flight. G450: Some G450 APUs cannot normally be operated in flight, even if others can. (There has been an issue with the APU enclosure sealant since 2009.)

[G450 Aircraft Operating Manual, §2A-49-10] The G450 Auxiliary Power Unit (APU) is a Honeywell 36-150 turbine engine composed of one compressor stage and one turbine stage with accessory mountings for a forty (40) KVA generator and Load Control Valve that provides compressor pressurized air for the aircraft pneumatic system bleed air supply manifold. The APU allows the aircraft to operate independently without requiring a ground air cart and external AC / DC power to start the aircraft engines. The APU also provides the ability to operate the air conditioning packs to cool or heat the aircraft interior without the necessity of starting the engines while preparing for departure. During flight, the APU can be used as a backup electrical power supply if a malfunction renders one or both aircraft engine generators inoperative. The APU will start and operate at altitudes up to thirty-seven thousand feet (37,000 ft). The APU is housed within a fireproof titanium container in the aft equipment bay. The air intake for the APU is on the top of the aircraft fuselage to the right of the dorsal fin forward of the vertical stabilizer. The APU exhaust is below the right engine pylon. The APU is mounted on two rails within the housing container and a hatch on the right side of the aircraft fuselage can be opened and the APU removed from the aircraft for maintenance by sliding the unit out horizontally on the mounting rails. However, if necessary, four removable panels on the APU housing container provide maintenance and servicing access with the unit in place. In addition, a panel on the left side of the aircraft can be removed to reveal a fifth removable panel on the APU enclosure that provides access to components mounted on the APU gearbox.

The Sealant Issue

[G450 AFM, §01-49-10, ¶1] The APU can be operated on the ground, during takeoff, in flight and during landing. In flight it is an optional source of electrical power via the APU GEN instead of one or both engine-driven generators. NOTE: APU operation is prohibited airborne, except for emergency operations if ASC 65 and subsequent for aircraft 4001-4171 excluding 4152 and Customer bulletin 137 and subsequent has not been complied with.

It appears to me that Gulfstream has given up all hope in resolving this issue with the FAA. There have been several false starts that were actually implemented but all have eventually failed. We are coming up on ten years for the affected serial numbers.

APU Input: Air

Just as with any jet engine, air intake is critical to the APU and just like everything critical on this airplane, the task of taking care of it is handed to a computer. In this case, the APU Electronic Control Unit handles when the APU inlet doors opens and by how much, and when it closes. The key takeaway is to give it time to do all that.

Figure: G450 APU air intake, (G450 Maintenance Manual, §49-12-00, figure 1)

[G450 Aircraft Operating Manual, §2A-49-20 ¶2.A.(1)] An air inlet door mounted on the top right side of fuselage in front of the vertical stabilizer provides an intake to the APU turbine. The inlet door is controlled by the APU Electronic Control Unit (ECU) and operated by an electrical actuator. The ECU opens the inlet when the APU MASTER switch, located on the APU panel on the cockpit overhead, is selected ON. When the air inlet door has opened, a READY light illuminates on the APU panel, indicating that the APU is configured for starting. When the APU is started on the ground, the air inlet door opens to 65° if none of the aircraft engines is operating. With one of the engines running above 20% the door opens only to 27°. If the APU is started while the aircraft is airborne, the amount of inlet opening is regulated by the ECU to match the air requirements for starting and combustion, depending upon aircraft speed and altitude. The door will fully open to 27° when the APU reaches 100% RPM. During shutdown of the APU, the air inlet door is fully closed only after APU rpm degrades below thirty-five percent (35%).

Figure: G450 APU air inlet door, (G450 Maintenance Manual, §49-12-01, figure 401)

With the engines not running, the door should open wide enough for you to see it from the ground. Once running, though not opened as wide, you should be able to see it from the tail camera.

One of the reasons you want to wait until 4% during shutdown before turning the APU master switch off is to allow the door to fully close. If left open, the intake may ingest enough water or other foreign debris to impact subsequent starts.

APU Input: Fuel

Fuel comes normally from the left tank and is consumed at about 200 pounds an hour, just under 30 gallons. There are two ways to stop fuel flow to the APU: the APU MASTER switch controls fuel at the source, at the fuel tank; pressing APU STOP or in case of a fire fuel is stopped at the APU itself but there is still fuel pressure entering the APU enclosure. (Unlike the GV/G550, there is no APU auto-cool-down so you don't really need the APU STOP button, though you should keep procedures consistent between airplanes when you can.)

Figure: G450 APU fuel tank hoppers, (G450 Aircraft Operating Manual, §2A-28-00, figure 3)

[G450 Aircraft Operating Manual, §2A-49-20 ¶2.D.] Fuel is supplied to the APU from the left wing tank using the left main fuel pump (the right main tank and pump may be used if the crossflow valve is opened). Pressurized fuel is routed through the APU fuel shutoff valve on the left wing rear beam structure that is controlled by the APU MASTER switch. A fuel line transits aft from the shutoff valve to supply the APU fuel control.

[G450 Aircraft Operating Manual, §2A-26-30 ¶2.C.] If a fire is detected within the APU enclosure, fuel is automatically shut off at the APU fuel control.

APU Input: Electrical

The ECU gets its power from the stronger battery but the starter always goes to the left unless you tell it to go to the right (by turning the left battery off). This comes in handy when starting in-flight, since you don't have to remember to turn a battery off like in the GV/G550.

Figure: G450 electrical system schematic, (Eddie's notes)

[G450 Aircraft Operating Manual, §2A-49-20 ¶2.B] The ECU is powered through the APU MASTER switch by the right essential DC bus through the APU PWR #1 circuit breaker or by the left battery bus through the APU PWR #2 circuit breaker (the ECU selects the highest voltage of the two power sources if both are available).

[G450 Aircraft Operating Manual, §2A-24-30 ¶2.D] The APU start contactor is powered only by the left battery during the starting process unless the left battery is manually selected off or not connected or installed, in which case the right battery will power the APU start contactor).

[G450 Aircraft Operating Manual, §2A-49-30 ¶4.B.(4)] Continuous operation of the APU starter, when powered by airplane batteries is limited to a maximum of three (3) consecutive start attempts. A one (1) hour cool down period must be observed before the next full starter cycle is commenced. APU start attempts when powered by an external DC cart are limited to a maximum of three (3) attempts. A fifteen (15) minute cool down is required between start attempts to protect airplane wiring. A one (1) hour cool down period must be observed before the next full starter cycle is commenced.

CAUTION: ALLOW FIFTEEN (15) MINUTES BEFORE ATTEMPTING ANOTHER APU START USING EXTERNAL DC POWER. THIS ALLOWS THE ELECTRICAL FEEDER CABLE FROM THE EXTERNAL POWER RECEPTACLE TO THE APU STARTER TO COOL.

NOTE: Successful consecutive starts are limited to 6 at 10 minute intervals per start.

APU Output: Bleed Air

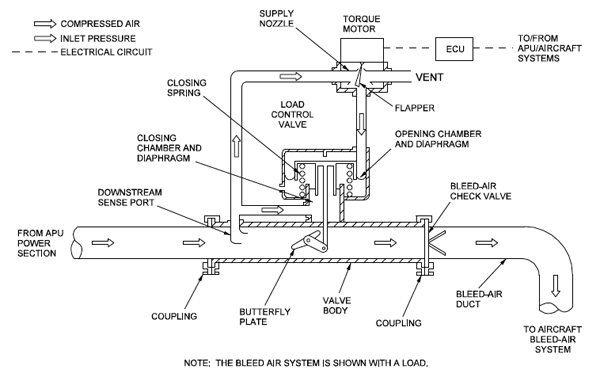

The APU produces bleed air that does not have a pressure or temperature target, it is regulated by the load control valve that gives you what it can, depending on electrical loads and ambient conditions.

The load control valve prioritizes electrical needs and will decrease air flow as required to keep the generator on line, or to prevent back pressure to engine bleeds. During an engine start, that can result in a hot start if the engine bleed switches are inadvertently left in the ON position.

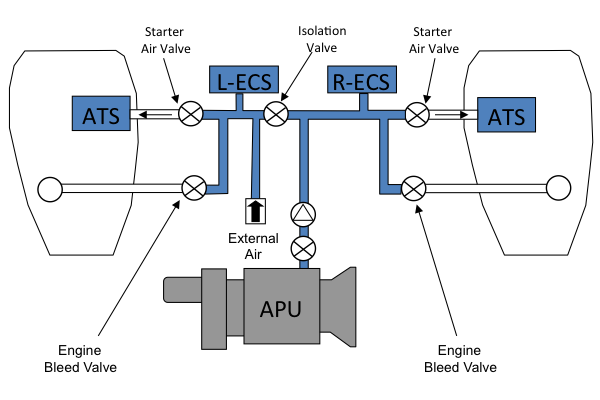

Figure: G450 APU Bleeds, (Eddie's notes)

[G450 Aircraft Operating Manual, §2A-49-20 ¶2.H.] The APU air system provides pressurized air for engine starting and operating the air conditioning packs on the ground. APU air is available after the APU has reached an operating speed of at least 100% rpm for at least 90 seconds. The ECU operates the APU load control valve to provide bleed air to the manifold supply duct when the push button switch labelled APU on the BLEED AIR control panel on the cockpit overhead is selected to ON. When the load control valve is open, the blue ON legend within the switch will illuminate. The ECU adjusts fuel flow at the fuel control to maintain the APU rpm at 100% when providing bleed air loads. The ECU will reduce pneumatic output in order to maintain correct electrical generator parameters if high bleed air demands degrade APU performance.

[G450 Aircraft Operating Manual, §2A-36-10] Air supplied by the APU or a ground cart is not regulated. The temperature and pressure of air from the APU is a function of APU speed and ambient conditions. APU bleed air is used primarily only on the ground for air conditioning and engine starting, but can be used as a source of air to assist inflight engine starts in abnormal operations.

On first glance this may seem to be one of those cut and paste errors in the G550-to-G450 history of the airplane. There are only two procedures in the G450 manuals which call for using the engine starters during flight and they both have more to do with hydraulics than the engines. But the plumbing exists to pneumatically start the engines in the air if you need them.

Figure: G450 APU load control valve, from G450 Maintenance Manual, §49-51-00, figure 3.

APU Output: Electrical

The APU generator, without any other AC source, powers everything on the ground and will power everything except the galley when in flight.

[G450 Aircraft Operating Manual, §2A-49-20 ¶2.G.] An oil-cooled generator mounted on the APU gearbox provides a source of AC power for use on the ground or in flight if an engine-driven generator is not available. The APU generator produces 3φ 400Hz 115/120v and can deliver up to 40kVA. The producing capacity of the generator is identical to those mounted on the aircraft engines - the only difference is that the APU generator does not have an Integrated Drive transmission since the APU operates at a constant speed (rpm). The generator can provide a full 40kVA output up to the limit of the APU operating envelope of 37,000 ft. When the APU has reached an operating rpm of 95% for at least 4 seconds, the APU is capable of driving the generator.

APU Output: Noise and Smoke

[G450 Aircraft Operating Manual, §09-01-10 Figure 2]

[Gulfstream Noise Information Manual, Pg US-5]

APU Starting

The in-flight procedure is identical to the ground procedure in the G450, since the starter will default to the left battery. (The is no need to deselect a battery as with the other aircraft in the GV series.)

Bleed air will be available 90 seconds after 100%, if you believe the G450 AOM (§2A-49-20, ¶2.H), or 95% if you believe the G450 AOM (§2A-49-30, ¶2.A(2)).

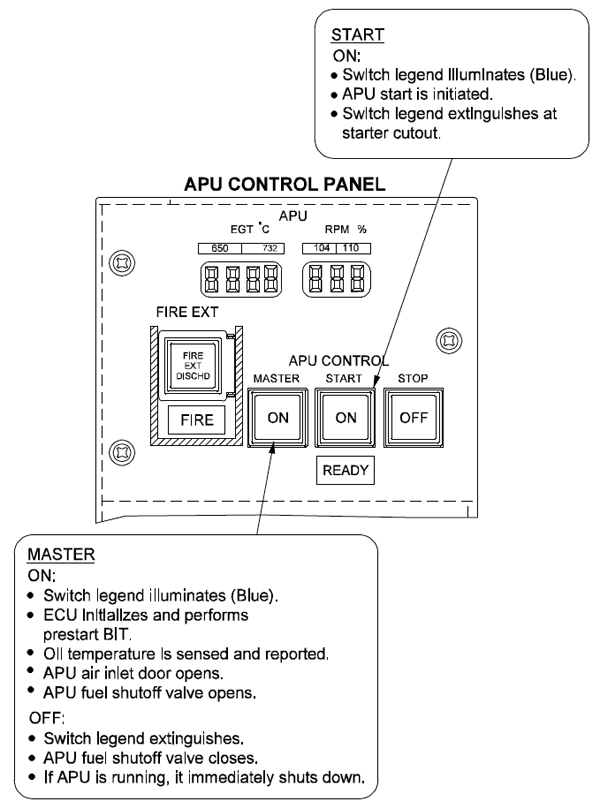

Figure: G450 APU control panel, master and start switches, (G450 Aircraft Operating Manual, §2A-49-00, figure 1, sheet 1)

[G450 Aircraft Operating Manual, §2A-49-20 ¶2.G.] The APU starter is electrically driven by the power source selected by the ECU. The starter is physically mounted on the accessory gearbox and spins up the APU through the gear interface. As the APU drive shaft rotates, the blades in compressor section draw in ambient air through the open air inlet and furnish pressurized air flow to the combustion chamber. Fuel and ignition are provided to the combustion chamber and the APU accelerates through the forces generated in the turbine section. The starter is disengaged when the APU reaches fifty percent (50%) rpm. Two igniters in the combustion chamber supply an intermittent, high voltage spark to ignite fuel during the start sequence. Operation of the igniters is fully automatic and controlled by the ECU. The igniters begin operating at five percent (5%), and remain energized until the APU has reached ninety-five percent (95%) rpm.

[G450 Aircraft Operating Manual, §2A-49-30 ¶2.A.(2)] The APU start proceeds in the following order:

The APU MASTER switch is depressed to ON and the blue ON legend within the switch illuminates.

The APU ECU performs a pre-start Built-In Test (BIT), opens the fuel shutoff valve at the left tank rear wing spar, and opens the air inlet door (nominal time to open the inlet door is 30 seconds). If the airplane engines are not running, the air inlet door will fully open to 65° in order to take in additional air for supplying bleed demands. With an engine running above 20% RPM, the air inlet opens to only 27° since it is presumed that an engine will supply any bleed air requirements.

When the BIT test is complete and the air inlet door and fuel shutoff valve configurations are correct, the ECU illuminates the READY light below START switch

When the READY light is illuminated, depressing the START push button closes the APU Start Contactor connecting the APU starter on the accessory gear box to the battery tie bus, initiating rotation of the APU. The blue ON legend within the START switch will illuminate as long as the starter is engaged.

At 5% rpm the fuel control shutoff valve opens and the igniters are energized.

At 7% the READY light extinguishes

At 50% rpm the ECU disengages the starter since the APU has sufficient rpm to accelerate using turbine stage energy, and the blue ON legend within the START switch extinguishes.

At ninety-five percent (95%) ignition is deactivated and the hour meter starts recording cumulative operating time of the APU

After reaching at least 95% rpm for 4 seconds the APU can support operation of the generator and after 90 seconds bleed air is available

Stabilized on speed rpm of 100% equals 62,000 rpm

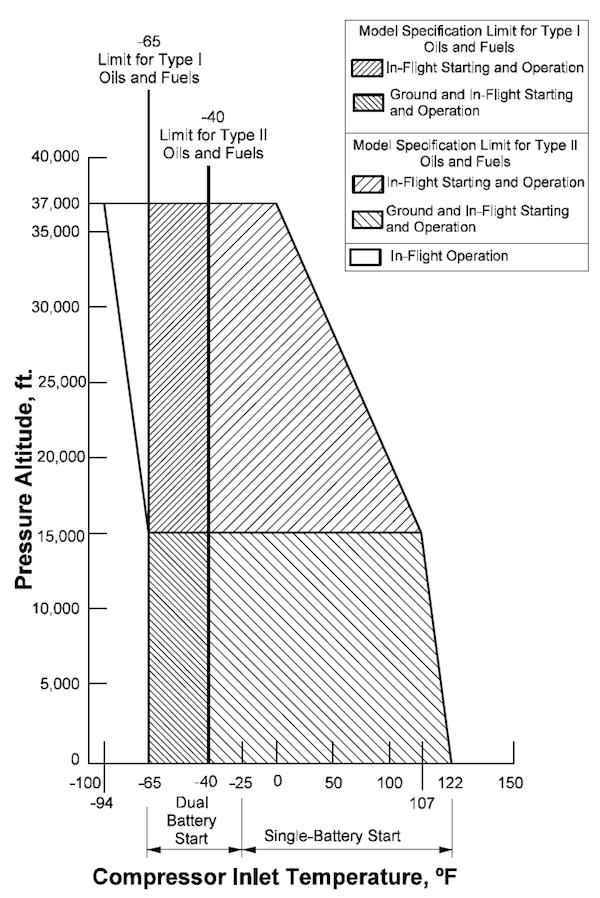

Figure: G450 APU start and operating envelope, (G450 Aircraft Operating Manual, §2A-49-00, figure 5)

[G450 Aircraft Operating Manual, §2A-49-30 ¶2.A.(3)] In-flight APU starts follow the same sequence as ground starts with the addition of the action of the Surge Control Valve. If the airplane is airborne and above 16,500’, at 60% rpm the Surge Control Valve will open to promote a smooth APU start. In the air the APU air inlet does not initially fully open during the start sequence - the door position is scheduled by the ECU based on APU performance requirements, and airplane altitude and airspeed, but the nominal opening value is 27°.

[G450 Aircraft Operating Manual, §2A-49-20, ¶2.H.] The APU air system provides pressurized air for engine starting and operating the air conditioning packs on the ground. APU air is available after the APU has reached an operating speed of at least one hundred percent (100%) rpm for at least ninety (90) seconds.

APU Stopping

The G450 does not have a programmed shutdown sequence like the GV/G550, the STOP button initiates an immediate shutdown. Hitting STOP leaves fuel pressure from the fuel tank into the APU enclosure at the APU fuel shutoff valve. Selecting the APU MASTER switch to OFF removes this fuel pressure at the source.

Figure: G450 APU control panel, stop switch, (G450 Aircraft Operating Manual, §2A-49-00, figure 1, sheet 2)

[G450 Aircraft Operating Manual, §2A-49-20 ¶2.A.(4)] The APU is shutdown by selecting the APU STOP switch to OFF, triggering the following sequence of events:

The ECU shuts down the APU by generating an overspeed signal in order to test the overspeed protection circuit. The overspeed circuit shuts off fuel to the APU at the fuel control unit mounted on the APU.

As the APU decelerates, the ECU also cycles the Surge Control Valve open and closed in order to maintain valve reliability. If the valve was not exercised during the shut-down sequence, it is possible that the valve would remain unused for extended periods since it normally opens only if the APU is operated above 16,500’.

When the APU decelerates below 35% rpm, the ECU closes the air inlet door. The nominal time for door closure is 15 seconds.

The ECU then initiates a 5 minute monitor period, continuing to supply power for EGT and rpm indications to ensure a complete shutdown. The ECU prompts an blue advisory CAS “APU Master On” message until the APU MASTER switch is selected off. If the APU MASTER switch is selected off before the 5 minute period expires, the message is not displayed.

At the completion of the shutdown process electrical power is removed from the APU

Limitations

[Airplane Flight Manual, §1-49-10]

Max EGT: 973°C (starting), 746°C (running)

Max RPM: 107%

Starter limits:

Battery: 3 consecutive, then 1 hour cooling

External DC: 3 with 15 minutes between attempts, then 1 hour cooling

[G450 Airplane Flight Manual, §1-49-30]

The APU generator can deliver 100% electrical power (40 kVA) on the ground or in flight from sea level to 37,000 ft (maximum altitudes for APU operations). APU generator loading will be limited to 85% between 30,000 ft and 37,000 ft at speeds greater than Mach .85.

APU Start Envelope: Guaranteed to 37,000'

APU Essential versus Non-Essential Mode

In the Essential Mode, the APU will not perform a protective shutdown for several items that would prompt a shutdown in the Non-Essential Mode: High EGT, high oil temperature, low oil pressure, loss of oil pressure or EGT sensor, reverse air flow, under speed, and loss of APU inlet door RVDT. If that happens, you would get an amber APU ESSENTIAL CAS message.

[G450 Aircraft Operating Manual, §2A-49-20 ¶2.A.] The ECU control authority for the APU has two operating regimes: non-essential and essential.

The non-essential regime is for normal ground operations when the APU is suppling electrical and/or pneumatic bleed air to aircraft systems. While operating in this regime the ECU will provide a full range of protective shutdowns to prevent damage to the APU. The protective logic is based on the assumption that for ground operations other sources can be used to supplant the APU to meet aircraft requirements, such as an external AC electrical supply or a pneumatic air cart.

The essential control mode is confined to APU operation while the aircraft is airborne. The essential regime is initiated by the aircraft combined Weight On Wheels (WOW) switch transitioning to the in the air state. In the essential control mode the ECU blocks some of the protective shutdowns of the APU since the control logic assumes that starting the APU while airborne would only be necessary during a malfunction or failure. Abnormal circumstances might require that the APU electrical power be essential to recovering from the condition, therefore the safe condition of the aircraft takes precedent over any possible damage to the APU.

NOTE: If the APU is operating in essential mode while the airplane is airborne, the APU will continue to operate in essential mode for fifteen minutes (15 min.) after landing in order for the flight crew to accomplish necessary securing procedures.

Protection System

[G450 Aircraft Operating Manual, §2A-26-20 ¶2.C.] The APU fire detector is a continuous element routed around critical areas within the APU container. The element consists of a tube filled with helium gas and a stabilizing chemical. The tube is sealed at both ends, resulting in a container with a constant internal pressure. Two sensors are installed in the end of the tube: one sensing high pressure and the other sensing low pressure.

If the gas within the tube is heated, molecular motion within the tube increases, resulting in a rise in pressure. A pressure increase above a preset threshold is indicative of a high temperature level in one or more areas monitored by the detector. The threshold corresponds to a pressure increase caused by a temperature of approximately 1,000°F over a small section of the sensor tube or by a temperature level of 450°F over the length of the sensor. When sensor pressure exceeds the threshold, a fire signal is sent to I/Os in MAUs #1 and #3 for initiation of MWS CAS visual and aural fire warnings. Hard wire signals are generated to illuminate the FIRE legend on the APU overhead panel, the red master warning light on the cockpit glare shield and if the aircraft is on the ground (weight-on-wheels), to the APU fire warning horn in the nose wheel well. The APU ECU automatically shuts off fuel to the APU if a fire is detected, bypassing the cool-down mode.

The second tube sensor monitors low gas pressure in the fire detector. If an APU malfunction or other failure causes a rupture in the tube structure allowing the escape of the gas within, the sensor will detect the resulting loss of pressure and signal a failure of the APU fire detector to I/O modules in MAUs #1 and #2 for MWS initiation of a CAS annunciation. Failure of the fire warning system will not automatically shutdown the APU.

[G450 Aircraft Operating Manual, §2A-26-30 ¶2.C.] Only the left fire extinguisher bottle is plumbed into the APU compartment. If a fire is detected within the APU enclosure, fuel is automatically shut off at the APU fuel control. The flight crew may discharge the contents of the left bottle into the APU by pushing in the guarded FIRE EXT DISCHD push button above the APU FIRE indicator light. When the left bottle is discharged, the bottle low pressure sensor will signal the activation of the amber L Fire Bottle Discharge CAS message and the illumination of the amber FIRE EXT DISCHD legend in the push button

Load Control Valve Logic

The GAC manuals make it clear you should not use the APU to start the engines with the engine bleed switches on, but they don't tell you why. The FlightSafety Maintenance Training Manual is the only thing in writing I've found that explains why and it does a pretty good job of it:

[G450 Airplane Flight Manual pg. 3A-13]

CAS Message: Bleed Configuration

Cause: Isolation valve is open with engine bleed selected ON

Corrective Action: Evaluate bleed configuration. if isolation valve is open for procedural requirements, select engine bleed(s) OFF as required.

[G450 Aircraft Operating Manual §2A-36-20 ¶2.D.] Control of the APU air is through the pushbutton switch labelled APU on the BLEED AIR Control Panel on the cockpit overhead. Depressing the switch while the APU is operating will open the Load Control Valve (LCV) of the APU, allowing bleed air drawn from the compressor stage of the APU to enter the supply manifold. The ON legend within the switch will illuminate when the LCV is open. The manifold isolation valve will also open, making APU air available for air conditioning pack operation and engine starting. Since there is no BAC for APU air and APU operation is governed by an Electronic Control Unit (ECU) that controls APU rpm to one hundred percent (100%) within temperature limits, the amount of bleed air produced by the compressor section will vary with density altitude. The APU must have reached ninety-five percent (95%) rpm for at least ninety (90) seconds in order to provide bleed air to the manifold.

[G450 Aircraft Operating Manual §2A-49-20 ¶2.B.] Once the APU has been started, the ECU monitors performance and adjusts operating temperature and rpm by commands to the fuel control, monitors the loading of the AC generator and provides bleed air to the pneumatic system, if selected, by varying the position of the Load Control Valve (LCV).

[G450 Aircraft Operating Manual §2A-49-20 ¶2.H.] The APU air system provides pressurized air for engine starting and operating the air conditioning packs on the ground. APU air is available after the APU has reached an operating speed of at least one hundred percent (100%) rpm for at least ninety (90) seconds. The ECU operates the APU load control valve to provide bleed air to the manifold supply duct when the pushbutton switch labelled APU on the BLEED AIR control panel on the cockpit overhead is selected to ON. When the load control valve is open, the blue ON legend within the switch will illuminate. The ECU adjusts fuel flow at the fuel control to maintain the APU rpm at one hundred percent (100%) when providing bleed air loads. APU air is drawn off of the compressor section of the powerplant and ducted through a check valve that prevents engine bleed air pressure from disrupting airflow within the APU. The ECU will reduce pneumatic output in order to maintain correct electrical generator parameters if high bleed air demands degrade APU performance.

[G450 Aircraft Operating Manual §03-03-20]

15. Engine BLEED AIR . . . OFF

[FlightSafety Maintenance Training Manual Ch. 49, pg. 49-49] An Amber "Bleed Configuration" EICAS message indicates the valves (APU LCV, L bleed air pressure regulating shutoff valve, R bleed air pressure regulating shutoff valve, and isolation valve) are configured incorrectly. Continued operation in this configuration could result in engine damage. The flight crew should check the BLEED AIR APU, MASTER CRANK, L ENG bleed, R ENG bleed, and ISOLATION switches and verify/correct switch selection.

The "Bleed configuration" (amber) message is displayed if either of the left and/or right bleed air systems are selected ON and the isolation valve is OPEN.

The ECU reads the speed of both engine HP compressors over the ARINC bus and, in this abnormal configuration, if either of the engines N2 speed is increased to approximately 20% HP (N2), the APU load control valve closes automatically. This protects the APU from bleed air back flow.

Attempting main engine start (MES) with "Bleed Configuration" (amber) alert will result in a hot start of the engine. As the LCV will be commanded to close once the engine speed reaches 20% N2.

APU Malfunctions

You need to understand Essential versus Non-Essential modes, how they differ when it comes to protective shutdowns, and the limitations before considering the possible malfunctions.

See: APU Essential versus Non-essential Mode.

See: G450 APU Abnormals.

Best Practices for APU Operation

The following is extracted from Breakfast Minutes, September 27, 2002. You can argue that these were written for the GII, GIII, and GIV and that is certainly true. But I think you can get some good information from the notes that follow; certainly better than the hearsay spread by some guy standing in front of a class with no more experience using the APU than you. I've highlighted the good parts.

Breakfast Minutes, September 27, 2002, Technical Update

By Darryl Smith, Project Engineer, Powerplant/ECS

GII/III/IV (ATA 49): Best Practices for APU Operation

Numerous questions have been received pertaining to improving the installed life of the GTCP36-100(G) APU used on the Gulfstream II/III/IV aircraft. This article offers recommendations to improve the installed life of the APU to gain maximum availability. Honeywell has provided below several different topics that may be of benefit on the causes of hot section damage.

General

The hot section life of the GTCP36-100(G) is mainly affected by damage to the turbine rotor and turbine nozzle. This type of damage is typically referred to as "Hot End Distress" or "Thermal Distress." Thermal deterioration or distress can also affect the interstage (labyrinth) seal plate. Typically, thermal distress, hot gas corrosion, and particle erosion are the causes for “Hot End Distress.” A number of material and component improvement programs have introduced better designs to the GTCP36-100(G) to increase the durability of the turbine area. These improvements were offered via Honeywell Service Bulletins. In addition to the available bulletins, there are a number of operational procedures that may improve the APU's installed life.

Thermal Distress

The APU’s hot section life depends on APU utilization. An APU that operates at maximum Exhaust Gas Temperature (EGT) will have a shorter life than one that operates at a part-load, lower EGT condition. Similarly, the number of thermal cycles has a direct bearing on the life of the turbine. Thermal cycles include starts and stops of the unit, as well as mode selections that result in step changes to the EGT.

Actually, high EGT is not the true cause for APU turbine distress. Turbine Inlet Temperature (T4) is the real parameter of interest. EGT is what the APU Electronic Control Unit (ECU) uses to maintain proper operation. However, ambient conditions will affect T4, but not necessarily EGT. For example, at maximum bleed load with the EGT at its upper limit of 1230ºF / 665ºC, the T4 temperature will be HIGHER on cold days than on warm days, due to the effect of air density on the APU's performance. Therefore, cold day operation of the APU can be potentially more detrimental than warm day operation.

Any operational procedural change that minimizes either the maximum EGT or the number of thermal cycles can be expected to help extend the hot section life. Ways of reducing the maximum EGT include the following:

Cabin temperature management:

Single air conditioning pack operation instead of dual-pack

Operating ACM in "Auto" mode instead of "Manual"

Commanding slow cabin temperature adjustment rates, either "pull-down" or "pull-up"

Minimizing bleed air system duct leakage.

In particularly hot or humid climates, it is recommended that the cabin door be closed to reduce the demand for air conditioning and APU operating time. All of these measures reduce the amount of APU bleed air delivery, which, in turn, causes the EGT to be lower.

Bleed duct integrity (although not part of the APU operation) is crucial to improving APU installed life. Bleed air leaks increase flow demand on the APU, resulting in a higher EGT. Regular bleed manifold checks are recommended to find and correct bleed air system leaks.

Thermal Cycles

The best way to avoid excessive thermal cycling is to plan APU usage in advance. It is better to run the APU in an “unneeded" idle state than to shut it down for a short period and restart it.

Sudden load changes cause high EGT spikes that result from the APU control system's response times. For example, if an APU is operating at steady-state with one air conditioning pack operating and then the second pack is added, the APU speed drops off because additional energy is being taken away by the increased bleed flow. This causes the APU speed to momentarily drop, which the ECU senses. When the speed drops below 100% governed speed, the ECU compensates by adding fuel to return the APU to full-speed operation. The addition of fuel increases the EGT, often resulting in a brief spike that exceeds the steady-state temperature. These spikes are not seen on cockpit gauges, but cause high overtemperature conditions for very brief times. These spikes in T4 may exceed the melting point of the turbine nozzle material.

Repetitive temperature overshoots will lead to erosion of the turbine nozzle vanes, which, in turn, damages the turbine rotor. Having either bleed switch on along with the APU Air switch can induce these same surges. In this condition, when the power levers are advanced and retarded, the APU will be commanded off and on, respectively. Gulfstream has published in the GIV Maintenance Manual, Chapter 36, recommendations on single bleed air source operations that will prevent these specific thermal cycles.

Cockpit procedures may be recommended to reduce the amount and degree of APU load changes that would include gradual cabin temperature selection changes, using one or two air conditioning packs throughout an APU cycle (not switching back and forth) and maintaining "Auto" mode ACM operation. "Manual" mode should be used only for troubleshooting procedures. In addition, Gulfstream has released GIV Aircraft Service Change (ASC) 390 Part 3 and production standard from aircraft 1310, which installs a bleed air limiting venturi in the ducting. This venturi reduces the degree of EGT overshoots that result from load transients. Additionally, Gulfstream has published in the GIV Maintenance Manual, Chapter 21, recommendations for single pack operation that will keep thermal cycles reduced.

Another APU air use that should be avoided is to warm up the aircraft wings or engine cowl. This operation puts the maximum load on the APU and is not recommended. It should be the last method of choice to de-ice wing leading edges or the cowl area when no air supply carts or hot air blowers are available to ready the aircraft for flight.

APU Surge

APU compressor surges will damage the turbine section. When a surge occurs, there is a very high spike in EGT, similar to the spikes described above. Surging can result from a number of conditions, including the following:

Hard carbon formation in the combustor that blocks turbine nozzle air passages

Combustor cap shield too close to the outer wall of the combustor

Inlet blockage or flow distortion entering the compressor

Foreign Object Damage to the impeller or diffuser

Excessive shaft load during very cold days or very hot days

Bleed air management procedures (refer to Honeywell Service Information Letter SIL APU-54)

If APU surges are encountered, the cause must be determined and corrected prior to continued service.

Combustor Abnormalities

Aberrations in the fuel delivery system or combustion chamber can adversely affect turbine section life. Factors such as a streaking fuel atomizer, air leaks at the combustor cap flange, atomizer gasket, igniter or drain fitting bosses, poor combustor-to-torus fit, or distortion/erosion of the combustor cooling skirts can all contribute to uneven flame distributions. Heavy carbon buildup in the combustor is an indicator of poor fuel atomization and may lead to APU surges. Any of the above conditions can result in a "hot streak" impinging on the turbine nozzle, which can exceed the melting point of the material. Compliance with Honeywell’s scheduled combustor/atomizer inspections is required and will help prevent these conditions from causing turbine section damage.

Torching Starts

Torching starts result from excessive fuel in the engine at light-off, which occurs typically following an unsuccessful start attempt. Conditions such as these will result in very high internal temperatures until the excess fuel is burned off. If torching starts occur, there is accelerated turbine distress due to the high gas temperatures during APU acceleration. If torching starts are encountered, the cause must be determined and corrected prior to continued service. Torching can be minimized, following an unsuccessful start, by waiting for the excess fuel to drain overboard before attempting a subsequent start.

APU Shutdown Procedures

The APU shutdown procedure has been the subject of much confusion since introduction of the GTCP36-100 Series APUs into service. Previous APU models, especially those that use an aft bearing ("hot-end bearing") behind the turbine rotor, required a "cool-down" period to allow the aft bearing to be cooled prior to the oil supply's termination. Shutting down such an APU without cool-down would cause coking of the aft bearing. The GTCP36-100 Series APUs do not use an aft bearing and, therefore, do not require the cool-down period. More importantly, a cool-down period is damaging to the GTCP36-100 Series APUs.

The correct shutdown procedure used on the GTCP36-100(G) APU is to command a shutdown from the existing operating condition and an existing APU load (either bleed or shaft) is NOT to be removed prior to commanding shutdown. The preferred method of shutting down the APU is to use the Overspeed Test switch. This procedure reduces the number of damaging thermal cycles and concurrently performs a test of the ECU's overspeed protection circuit.

De-Icing Fluid Ingestion

This subject is covered in depth in the Honeywell GTCP36-100(G) APU Maintenance Manual (49-21-89), the Gulfstream Maintenance Manual, Chapter 12, and the applicable Airplane Flight Manual Cold Weather Operations section. APU ingestion of de-icing fluids or aircraft wash solutions that contain corrosive agents is to be avoided at all times. Rapid hot corrosion of the turbine can result, as well as unprotected overspeeds, leading to very costly repairs. In addition, washing agents that contain chlorine will attack the titanium compressor impeller and possibly lead to its failure during operation.

Main Engine Starting

Main engine starts that are slow should be avoided, as the longer the APU must be at maximum temperature, the more damage that will occur to the turbine section. Regular monitoring of the start cycle time is recommended in order to identify when the start time is getting lengthy, which will allow a quick correction to the situation.

References:

Gulfstream G450 Airplane Flight Manual, Revision 35, April 18, 2013

Gulfstream G450 Maintenance Manual, Revision 18, Dec 12, 2013

Gulfstream G450 Operating Manual Supplement, G-450-OMS-02, Extended Operations (ETOPS) Guide, Revision 2, April 2, 2009

Gulfstream G450 Performance Handbook, GAC-AC-G450-OPS-0003, Revision 20, November 30, 2011

Gulfstream G450 Quick Reference Handbook, GAC-AC-G450-OPS-0003, Revision 34, 18 April 2013

Gulfstream G450 Weight and Balance Manual, Revision 3, March 2008